Your Industry-Leading PCB Fabricator & Manufacturer

3 min read

Your Industry-Leading PCB Fabricator & Manufacturer

Our goal is to be the top 5 PCB manufacturers in China. Thanks to the ten-year fabrication experience and know-how of its staff , JHDPCB has been providing customers with high-quality PCBs. Our professional customer service team provides 7×24 hours one-stop PCB manufacturing service for your PCB needs, from prototype PCB to all types of PCB. Please contact us and send your Gerber file along with your request for material and quantity, and we will give you a good quotation shortly. Get a quick quote entry.

You can read more about our PCB manufacturing capabilities and production.

From small batches to large batches, different types of PCBs to multi-variety assembly, we will take advantage of our automated high-end precision equipment and ingenuity to help all customers solve PCB needs. All production processes are IPC Class 2 & 3 compliant and ISO 9001:2015 certified. A complete quality control system and 100% PCB testing program will ensure that every order you entrust is completed perfectl.

JHDPCB knows that an efficient and powerful PCB production line is inseparable from many reliable precision equipment. Therefore, while strengthening the education of team members, we are not stingy in equipment and continue to introduce top-level high-precision equipment.

Large-scale production reduces costs and provides you with cost-effective PCB.

We constantly update production technology to improve production efficiency,and ultimately reduce costs. Our goal is to produce high-quality PCB with lower price by large-scale production.

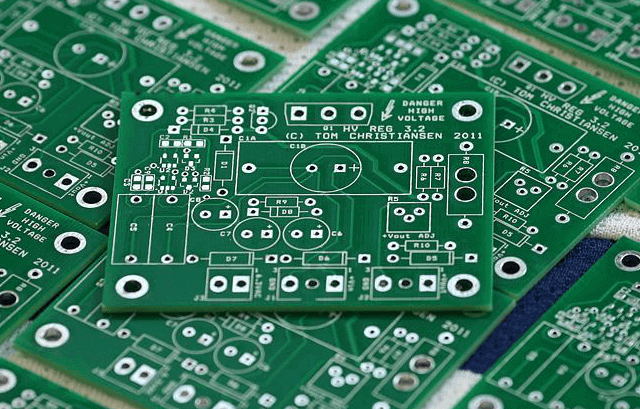

What Is A PCB Panel?

PCB panel, also known as PCB array. Considering the efficiency of PCB manufacturing, panelization is essential. Aggregating multiple PCBs for fabrication on one large board is known as panel creation. PCB panelization is a fabrication technique which makes it easy to pass through the assembly line owing to the fact that the smaller PCBs are fabricated as a single array by being integrally connected together. And it’s so easy to separate or remove each board from the array so that packaging or installation in products. Alternatively increasing the width to accommodate the assembly line by a PCB processing edge around an individual PCB. Panels are typically applied to high volume PCB production. PCB panelization not only improve total output , but also allows designers to change dimensional to improve overall pcb panel utilization and save costs. There are always different board types to choose from during the PCB order placement process: single board design or panel design. Because some boards are irregular, the panels can reduce the time cost and labor for production and testing. Additional planning is required if the PCB is too large for the panel or if there are other special requirements.

Advantages of creating a PCB panel.

To panelize pcb not only helps smaller boards to adapt to standard production procedure, but also increases production efficiency. And there are some advantages of PCB panelization, including:

Save time & money:

PCB control panel enables you to spend less money and time owing to mass production. Building many boards in a large panel is more cost-effective than building them individually. Meanwhile, it can also save the time, money and labor.

Improves Work Efficiency:

As a means to improve PCB productivity, it is a common practice to install multiple smaller copies of the printed circuit board in the fabrication of panel. It is an effective way to fabricate and assemble the boards rather than manufacture them one by one.

The identical material and stack-up configuration must being included in panels as the printed board. The important thing is to choose the panel size (whether small or large) which best fits your needs of printed circuit board, various manufacturing and assembly processing. If you can fit more boards into PCB panel, the more efficient of the manufacturing you will own.It will also reduce waste of panel space.

Improve Produce Quality:

PCB paneling is not an optional fabrication process, because you will need to panelize them if you produce large quantities of similar circuit boards. Due to the goal of panelization is to board uniformity, related components are placed on different boards at the same time, there will be less of fault occurring in the manufacturing when you use panelization. When you produce smaller circuit boards and need to ensure the components are similar and uniform, PCB panelization will occur. This process helps to guarantee the quality of the product.

Product safety:

Panelization can offer protection from vibration and shock or mechanical stress for every individual printed circuit board. If you use laser depaneling, these damages can even be completely avoided.