What Is SMT Assembly?

3 min read

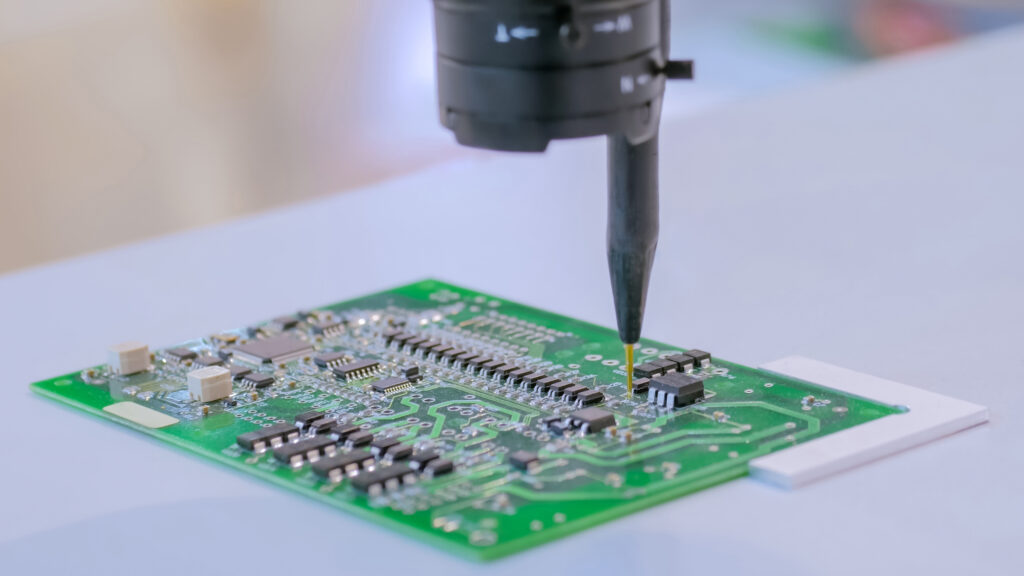

SMT is the abbreviation of surface mounting technology, which is called surface mounting or surface mounting technology. It is the most popular technology and process in the electronic assembly industry. SMT assembly has a wide range of applications. It is an alternative to the through-hole method of PCB assembly. This is a method to produce electronic circuits by placing components directly on the surface of the circuit board, allowing the components to be directly mounted on the surface mount PCB. This technology can make components small and convenient, so it is famous for its high mechanical strength. If you want high-speed circuit, SMT printed circuit board will be the first choice of you.

How SMT Helps The PCB Assembly Process?

The application of the PCB SMT assembly process will bring the following benefits to the PCB circuit board:

Easy to assemble-

Since the component lead surface is mounted on the pad, there is no need to form a lead, which makes SMT assembly easier and faster. In through-hole technology, the opposite is true.

Reliability-

SMT is generally more reliable than through-hole components because it is not susceptible to vibration and shock. At the same time, the chance of component failure due to cold solder joints can be greatly reduced by using solder paste instead of molten solder.

Be able to use fine pitch elements-

In general, excellent spacers are allowed to be used in SMT assembly, which is never possible with through-hole technology. Its main advantage is that it can be used in small, high-density components.

Multi functionality-

SMT assembly technology is widely used in consumer electronics, telecommunications, medical equipment, industrial control systems and other industries.

Ability to use mixed technology PCB–

With the help of SMT assembly technology, PCB combining through hole and surface mount components is also possible. For example, it is very practical to use two or more types of applications at the same time when space is limited. The best example is in building a mixer board that contains fixed controls (through holes) and sliding fades.

PCB ASSEMBLY OVERVIEW

The complete PCB generally contains two parts, One is the production of bare PCB boards, and the other is the assembly and packaging of electronic components. After the bare circuit board is made, it is the assembly and packaging of the PCB.

What Is PCB Assembly?

We have talked about how PCBs are made through PCB mechanics which include several processing steps. However, further processing is required before the circuit board can be used, that is, assembly PCB. The bare board will be made with fiberglass, copper lines and other metal parts, held together with epoxy resin and insulated with a solder mask. The solder mask turns the bottom surface into green.

After a PCB is prepared, electronic components and parts can be assembled on it. And some electronic components are going to be mounted on the PCB. Then this board is called PCBA and can be used for electronic products. Therefore, PCB Assembly refers to the manufacturing procedure of connecting electronic components to the printed circuit boards by using soldering, PCBA for short. The upgrade of electronic products has led to an increasing demand for PCB assembly prototypes.

How To Assemble PCB?

PCB assembly process consist of adding solder paste to the board, picking and placing components, soldering, inspection and testing. The whole assembly process need to be monitored to ensure highest quality of the products are produced. (PCB prototype assemblies are early samples of products built with the sole purpose of testing design ideas to see if they work)

PCB Assembly Inspection Checklist.

In the assembly process of PCB SMT, BGA, etc., a comprehensive inspection is required. Includes bare board inspection and electrical inspection during component assembly. Real-time inspection can ensure the smooth progress of the subsequent assembly process. Commonly used main inspections and tests include visual inspection, AOI (Automated Optical Inspection), X-ray inspection and ICT (In-Line Inspection).